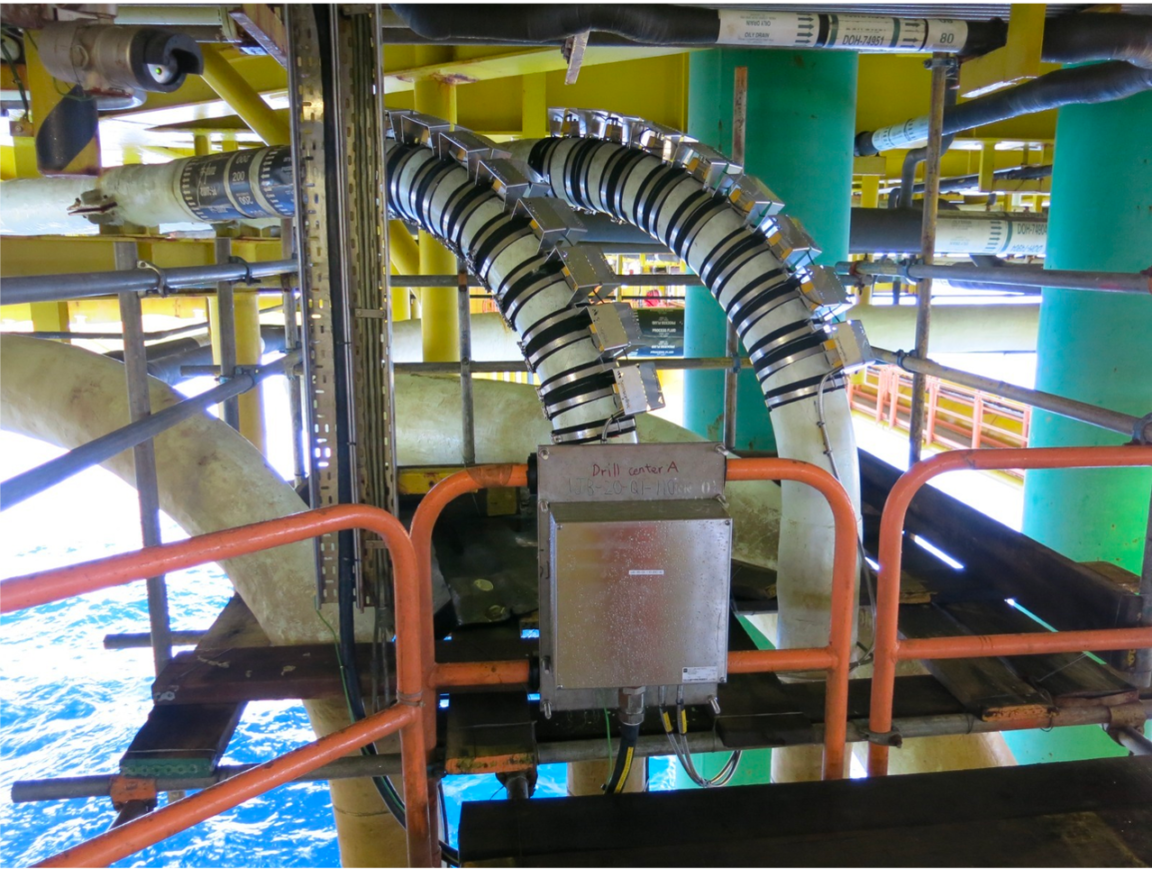

High temperature, non-intrusive wall thickness solutions for in-service corrosion and erosion monitoring. The system comprises of high temperature, ultrasonic transducers, permanently mounted to process pipework, vessels and other structures coupled with a range of instrumentation options from spot reading, through to online, real-time wireless monitoring using industry standard WirelessHART protocol.

Erosion monitoring device locations should be selected based on the highest risk areas determined by the plant corrosion engineering / integrity teams based on previous experience, simulation or areas found during manual inspections.

Locations where the process is flowing at a higher velocity such as downstream of the choke are often considered to have an increased risk for erosion, particularly where the presence of sand has been detected previously or may be suspected/expected. Other areas at high risk for erosion may include locations with rapid changes in direction such as small radius bends, and T-sections.

Generally, ideal locations for intrusive erosion monitoring devices are centre of the line at a minimum of 10 x pipe ID downstream of bends, or T-sections where flow velocity and sand concentration may be higher. As with other intrusive devices, wake frequency/drag calculations can be considered when determining maximum device lengths.

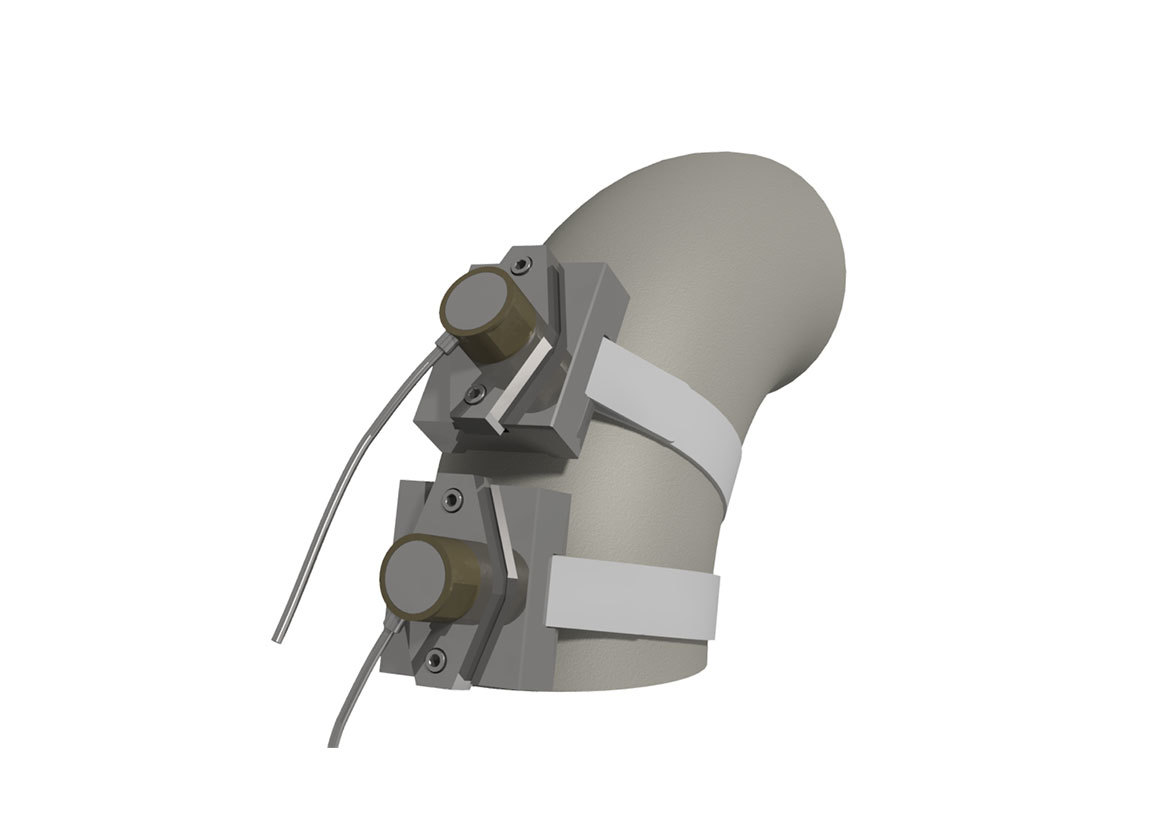

For non-intrusive devices, monitoring locations may include outside radius of bends, and outside and inside of T-sections and at other high velocity areas where the presence of sand may be known or suspected.

There is a lot to consider when specifying a Corrosion & Erosion system. With tens of thousands of product variations and variables to navigate it can seem like a daunting process.

Axess’ Kickstarter Program was developed as a tool to assist with generating part numbers and bills of materials, provide customers with an online platform for submission of requests for quotation and to help people get started in the industry.

Register with Axess for a Kickstarter login and make life less stressful.