For decades, the conventional practice of installing intrusive monitoring systems has remained largely unchanged. We present a breakthrough in the field of corrosion monitoring with the Horizon Access Fitting. Designed to provide bottom-of-line (BoL) monitoring with a side-of-line (SoL) entry, this innovative approach addresses the technical challenges and safety concerns associated with traditional 6 o'clock installations. We explore the evaluation of Horizon Fitting technology within a client’s processes, its technical advantages, compatibility with existing tools, and significant safety benefits. Our findings recommend a shift in industry standards, as the Horizon Access Fitting offers a more accurate, safer, and more reliable method for monitoring pipeline integrity.

Introduction

Intrusive corrosion monitoring plays a critical role in the management of industrial pipelines, particularly those handling wet hydrocarbon processes. The traditional positioning of access fittings has led to numerous challenges and compromises in data quality and safety.

Technical Challenge

The location of monitoring points greatly impacts the accuracy of corrosion data. The most corrosive segment of a wet hydrocarbon system is typically found at the 6 o'clock position. However, monitoring at this location faces clearance issues, risk of clogging due to debris accumulation, and potential safety hazards. The client also wanted to achieve BoL monitoring with limited access to the bottom of the pipe.

Traditional Monitoring & Its Pitfalls

Various installations, from alternative 3/9 o'clock positions to inverted-tee connections, have led to unreliable and sometimes dangerous outcomes. Accumulated debris, blockage risks, and, most critically, the failure to capture representative data pose pressing concerns for the industry.

The Innovation: Horizon Access Fittings

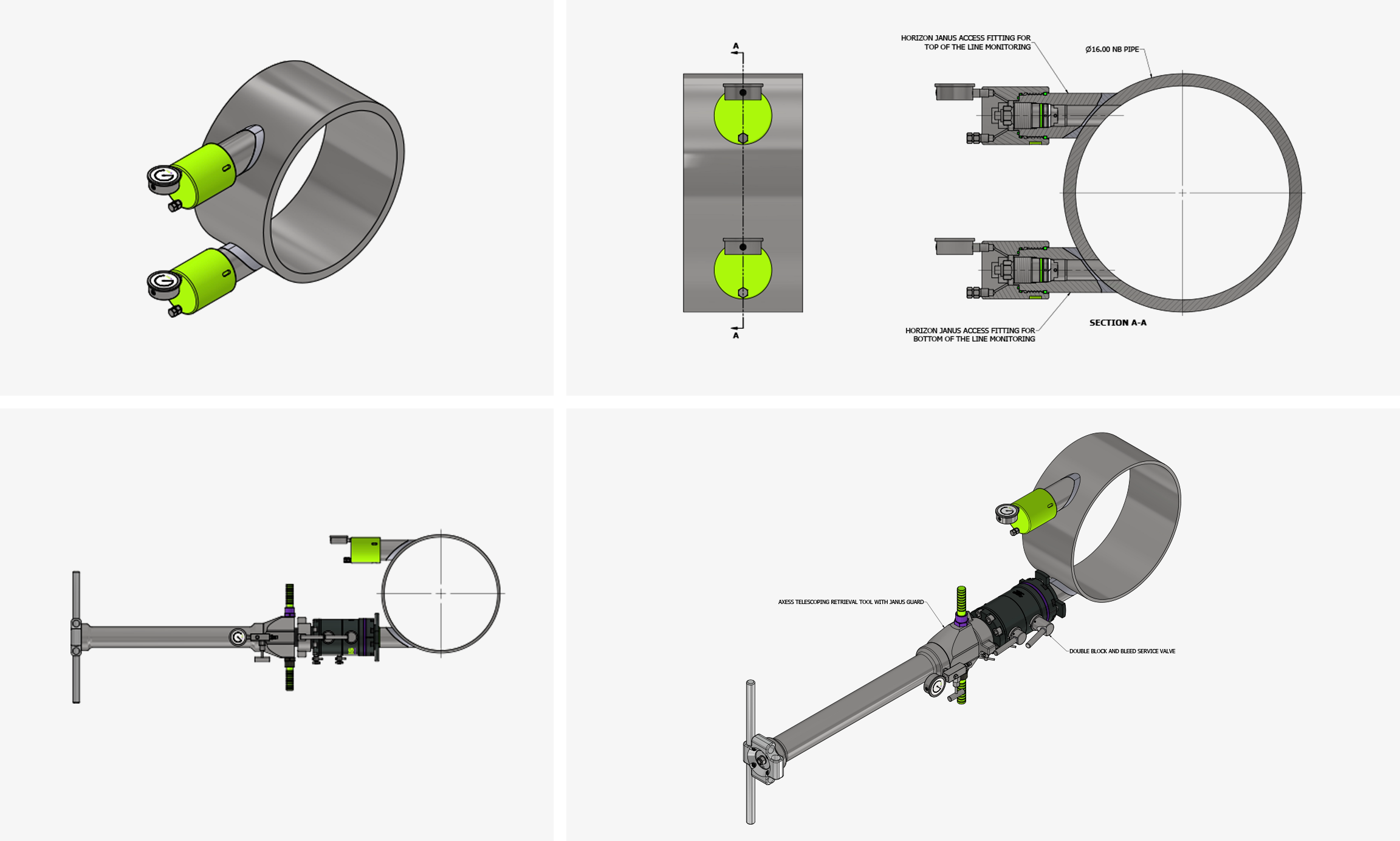

The Horizon Fitting represents a step-change innovation — its unique design facilitates monitoring from the bottom while accessing the pipeline from the side. This resolves issues with ground clearance and minimizes the risk of debris build-up, all without compromising on data accuracy or operational pressure requirements. The Horizon Fitting can also be utilized for top-of-line monitoring, often reducing the need for scaffolding and fixed platforms. When utilized for sampling, the side-of-line entry ensures clean samples with a reduced risk of blockages.

Implementing the Horizon Fitting translates to reduced risks associated with retrieval tool 'pistoning,' wake frequency issues and the requirement of heavy retrieval equipment. Shorter and more manageable device lengths lead to a safer work environment for industry professionals. The human factor should also be considered in terms of manual handling and working at heights.

Over the years access pits have also presented a high risk for technicians, particularly where toxic gases are present. A recent poll suggested that this was one of the top concerns related to BoL monitoring, onshore.

Key Features

High-Pressure Performance

Built to withstand extreme pressures, this access fitting ensures seamless operation even in the most demanding environments.

Corrosion Monitoring and Sampling

Facilitates effective monitoring and sampling of corrosion levels, allowing for informed maintenance decisions and minimizing downtime.

Janus Double Seal Feature

The unique double seal design removes the need to shut down operations for maintenance, ensuring uninterrupted monitoring and sampling.

Protected from Environmental Factors

The Janus seal provides an extra layer of defense against external elements, extending the service life of the fitting.

Elimination of Challenging Bottom Pipe Fittings

Our innovative side-entry design eradicates the complications associated with bottom pipe fittings, such as debris blockages preventing pressure equalization.

Benefits

Enhanced Safety

The reduced risk of debris accumulation lowers the risk of operational interruptions, fostering a more secure working atmosphere.

Simplified Process

The elimination of bottom pipe fittings simplifies the monitoring approach, leading to operational efficiencies.

Increased Reliability

The Janus double seal feature bolster’s safety under high-pressure conditions. A double block and bleed valve delivers little benefit over a single ball valve, if not utilizing Janus sealing technology.

Superior Corrosion Monitoring

Advanced capabilities for proactive corrosion oversight facilitate extended asset longevity.

Unique Patented Design

Our patented design heralds the first notable development in corrosion monitoring technology, setting a new industry benchmark for the next half-century.