AX2HP & AX2HPH

Access Fittings

Axess offers a complete range of high pressure access fitting assemblies for installation of intrusive corrosion monitoring, chemical injection, and sampling devices.

The product range comprises both the 2" mechanical system as well as the 2" hydraulic system. The 2" retrievable access system is a high pressure access system for the installation of devices into pipework and vessels. The system allows insertion and retrieval of the devices under pressure, enabling monitoring to be maintained continuously without the need to shut down the process. Axess 2" retrievable access system products are compatible and interchangeable with industry standard products.

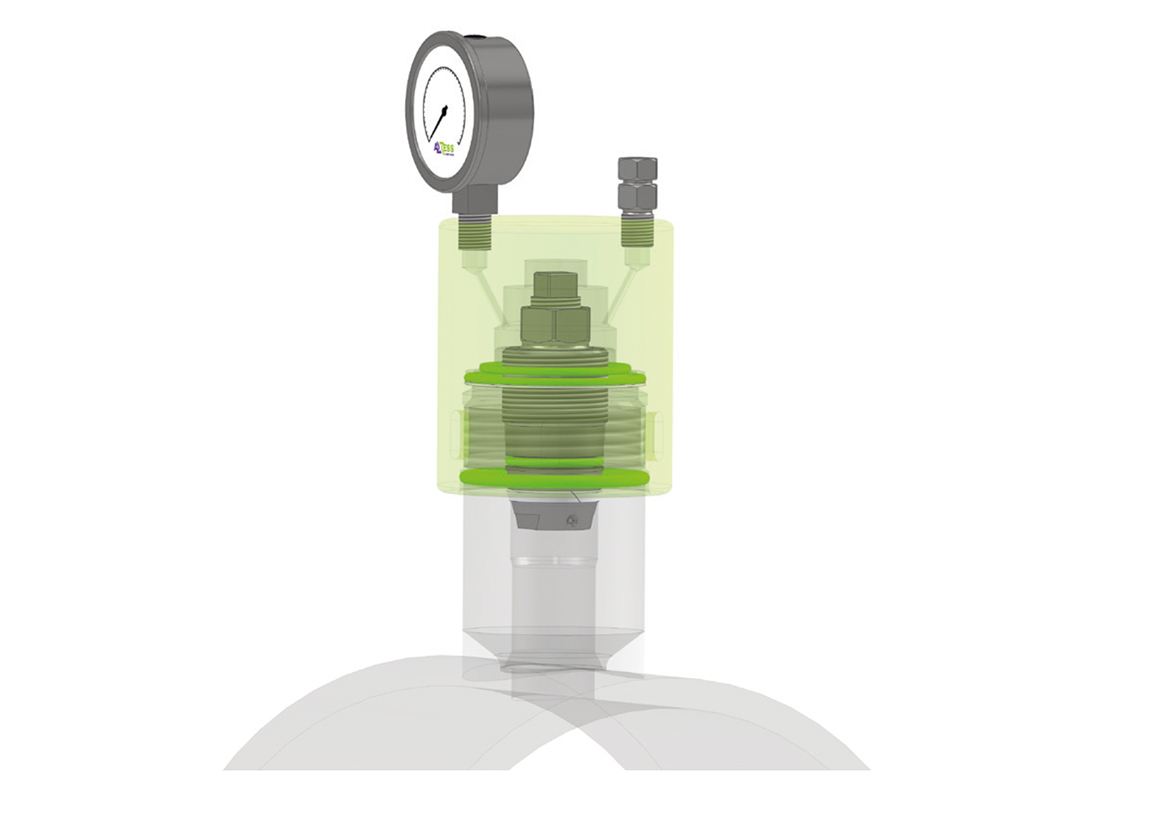

Janus

Enhanced Sealing Access Fittings

The unique patented design is the first advance in high-pressure access fittings in decades and enhances safety by providing extra layers of protection against process entering the environment, and environment damaging the access fitting.

An external 3" ACME thread enables installation of portable isolation valves used while retrieving devices under line pressure. It is common for double isolation valves to be specified, yet these valves do not provide a double seal at the access fitting. The Janus™ fitting solves this problem with a radial sealing surface for the secondary seals installed in the Janus™ service valve or retrokit designed to attach to existing service valves.

A third seal is fixed to the access fitting providing external thread and sealing surface protection from the environment. Axess provide the Janus advanced sealing system as standard unless legacy access fittings are specifically requested.

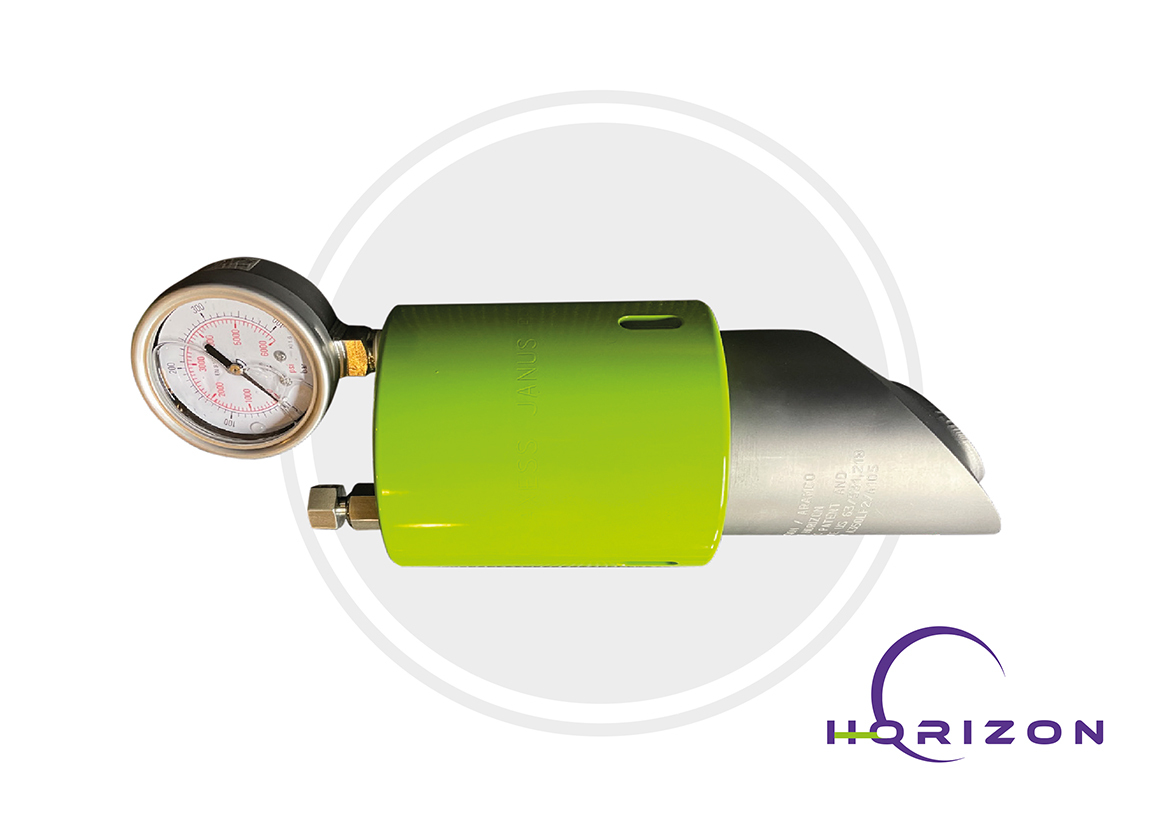

Horizon

Side Entry for BOL and TOL Monitoring

This patented design removes the need to position access fittings at the 6 o’clock position for bottom of the line (BOL) monitoring or sampling, or 12 o’clock for top-of-the-line monitoring (TOL). The benefits are significant and range from safety, integrity, and more accurate data. Engineers consider side entry as the safest and easiest type of fitting to design on pipework and the Horizon fitting removes the need for access pits and in many cases scaffolding.

Common alternatives to BOL monitoring is to install tee trap systems which provide questionable data as the monitored fluids can be stagnant and not representative of the process flow. Multiple joins and valves add to integrity management inspections and these systems may also freeze in some climates.

Standardizing on Horizon fittings will reduce device lengths and ultimately lead to shorter and lighter retrieval equipment, reducing cost and risk.

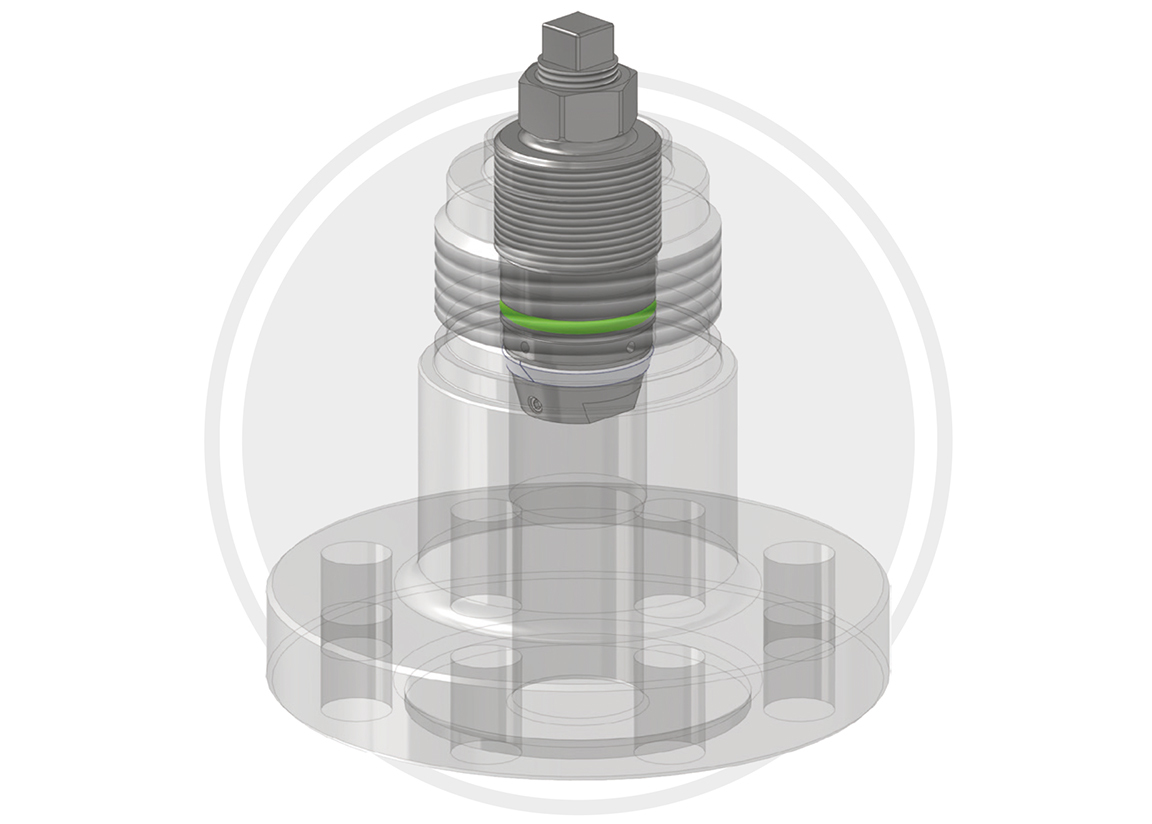

HP Mechanical

Access Fitting

Mechanical access fittings have an internal 1." UN parallel thread to receive carrier plugs that connect to various devices and seal into place at pressures up to 10,000 PSI (689 Bar) and temperatures up to 204 °C (400 °F). The access fitting and plug body can be supplied with an ACME plug thread to special order.

An external 3" ACME thread enables installation of portable isolation valves used while retrieving devices under line pressure and pressure retaining covers providing secondary isolation.

HP Hydraulic

Access System

The Axess hydraulic access and retrieval system provides a complete solution for the online safe, reliable installation and retrieval of probes and coupons from high pressure piping, and vessels at pressures up to 10,000 PSI (690 Bar) and temperatures of up to 204 °C (400 °F).

Axess 2" hydraulic access products are compatible and interchangeable with industry standard products also supplied by other vendors.

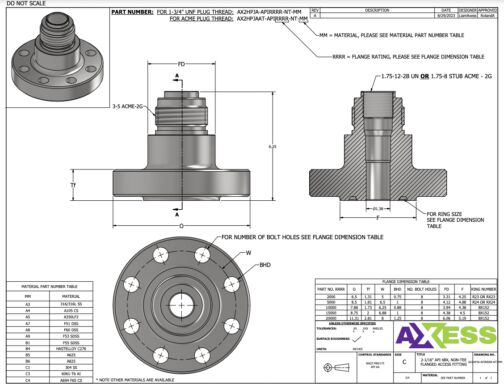

Carrier Plugs

Hollow or Solid (standard 1-3/4 UN & ACME)

The Hollow or Solid Plug provides the pressure seal in the access fitting and is the carrier for the corrosion monitoring device (probe or coupon holder). The primary packing seal is made from PTFE (25% glass filled) as standard but are available in a range of materials including metal seals for high temperature service. The mechanical solid plug has an O-ring that must be selected according to application.

Hollow plugs are used for online probes like ER (Electric Resistance) and LPR (Linear Polarization Resistance) probes.

Solid plugs are used for passive monitoring devices including weight loss coupons, bio coupons and injection/ sampling equipment. Axess hollow and solid plugs are available in 316 SS and Duplex material as standard. Plug threads are coated and Axess experts can assist with material selection to reduce or eliminate galling risks.

Special plug designs are available for high velocity applications based on results from wake frequency calculations. Please consult Axess for more information.

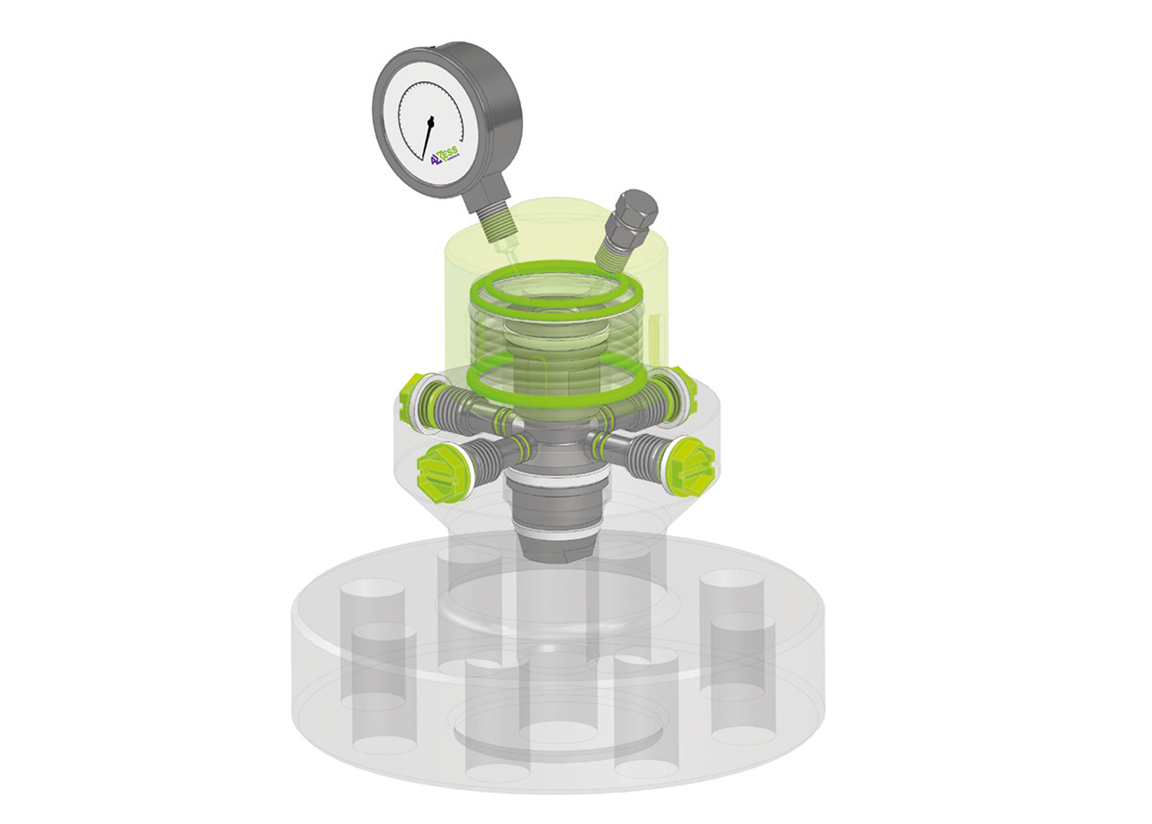

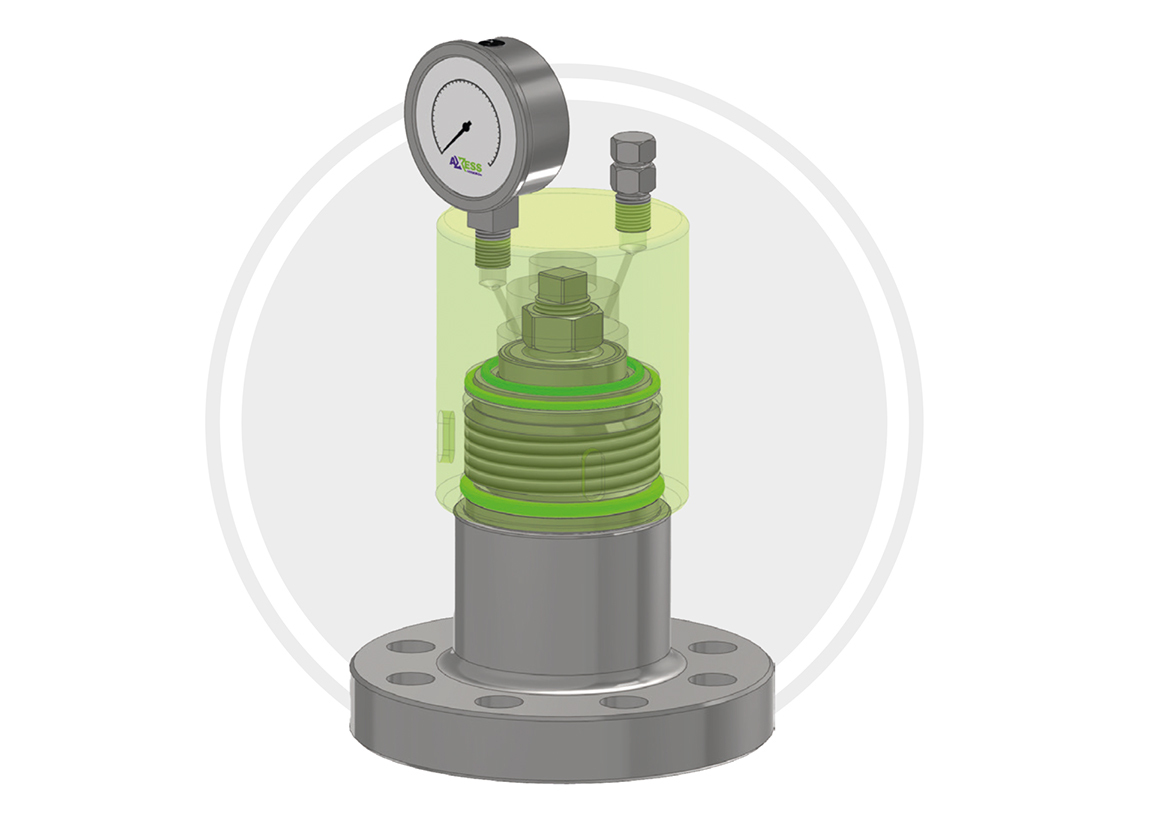

Safety Cover

Access Fitting

The Pressure Retaining Cover provides secondary isolation up to 10,000 PSI / 689 Bar (subject to material). The pressure gauge indicates whether the plug seals have leaked and the bleed port allows bleed o prior to removal.

2-hole pressure retaining covers are used for coupon locations and incorporate a pressure indicator and bleed plug for assessment and servicing. All components are available in numerous materials.

For probe locations 3-hole pressure retaining covers also include a central hole for installation of a probe adaptor. Lighter duty covers in vinyl or carbon steel are available and are recommended for thread protection during transport and installation only. Axess recommends all HP Access Fittings, once commissioned, are installed with Pressure Retaining Covers. The covers are coated as standard and Axess can also coat to client specifications.

Side Tees

Access Fitting

2" HP access fittings are commonly used for the injection of chemicals to process or for sampling from the process. Sand probes also utilise tee-type access fittings. The ability to maintain or change the injection head under pressure can save time and cost and ensure optimum flow.

The tee can be between ." and 1" diameter and configured to suit the type of service. Options for NPT threaded, socket-weld, butt-weld, and flanged tees are available. Where threaded connections are contemplated, the relevant piping codes should be consulted to ensure these are acceptable.

The addition of a tee adds between 1 and 3" to the height of the standard access fitting (5.") according to the diameter and rating. Where real estate is in short supply, Axess provides Direct Injection and teeless sand probe fittings that remove the need for a side tee connection.

Please see the Teeless Kamikaze and Chemical Injection and Sampling Datasheets for more information.

Seals

Access Fitting

Correct seal selection is vital to ensure safety and longevity of service. Axess has innovated in this area and developed our Janus enhanced sealing system. This adds additional seals to the access fitting cover to increase safety, protect the environment from spillage in case of leaks and to increase access fitting life by protecting the cover threads.

Kickstarter

There is a lot to consider when specifying an Injection & Sampling system. With tens of thousands of product variations and variables to navigate it can seem like a daunting process.

Axess’ Kickstarter Program was developed as a tool to assist with generating part numbers and bills of materials, provide customers with an online platform for submission of requests for quotation and to help people get started in the industry.

Register with Axess for a Kickstarter login and make life less stressful.