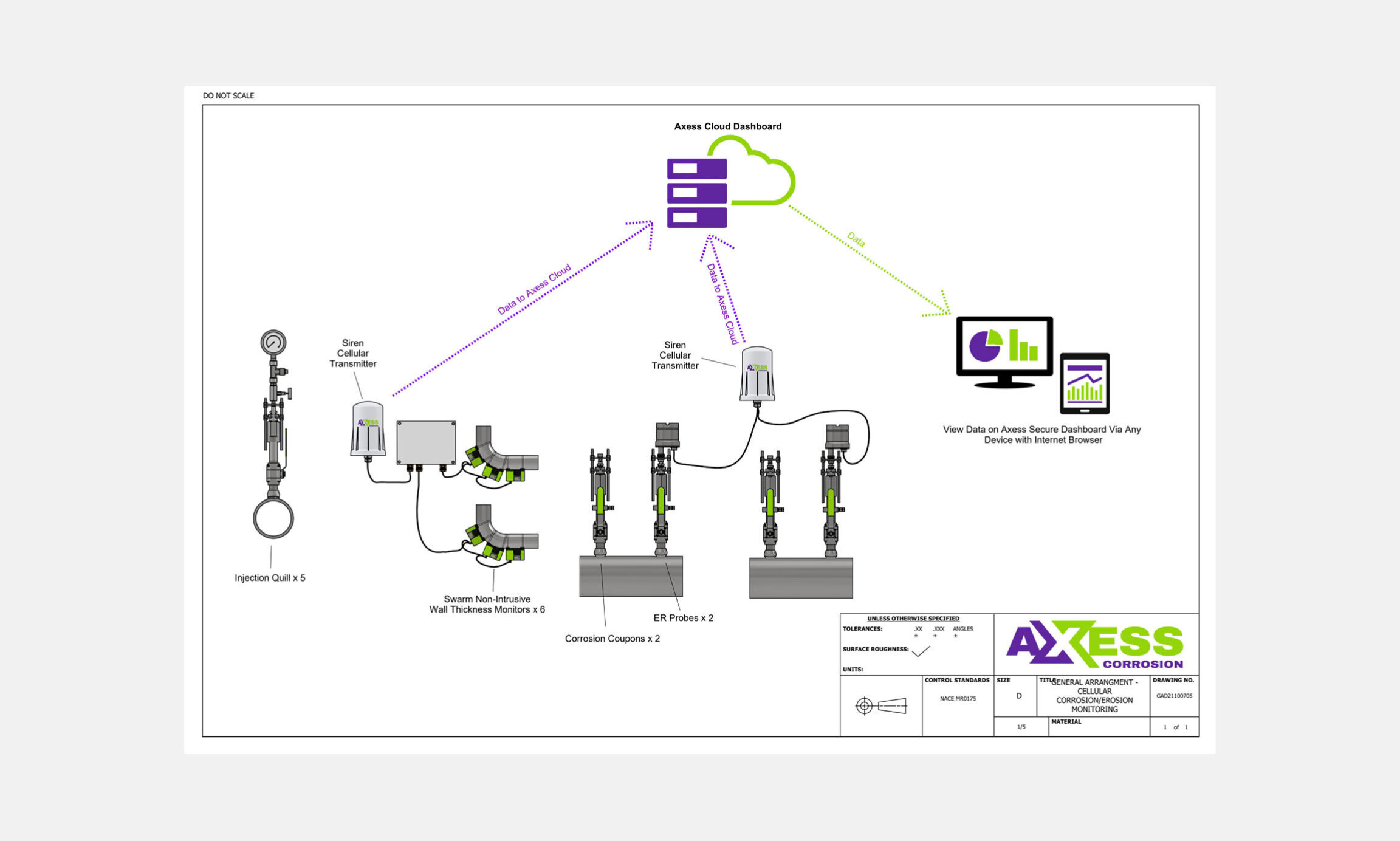

Axess offers a wide range of wireless and remote monitoring solutions utilizing intrusive Electrical Resistance (ER), Linear Polarization Resistance (LPR), and Galvanic probes and non-intrusive ultrasonic pipe wall thickness monitors. Systems are tailored around specific customer and site requirements using industry standard WirelessHART protocol for local deployments and 900MHz radios, or cellular communications for remote monitoring. Axess instruments are designed to deliver your data in the simplest and most cost-effective method for your needs. Online communication protocols include 4-20mA, HART, RS-485 Modbus, WirelessHART, LTE Cellular or Satellite. Integrated with pressure, temperature and flow meters, Axess deliver an integrated remote process monitoring solution.

For areas where basic historical information is good enough, data collection units are available. When the current metal loss or wall thickness value is all that is required, and monitoring is not, then spot measurement handheld units are also available. Data can be delivered from our range of instruments directly to your networked DCS, a cloud-hosted dashboard with alarm settings for email and SMS notifications and GPS coordinates, or hosted by Axess and reported through a data subscription package.

Axess work to engineer bespoke solutions to meet customers data needs. Multiple communications options are available using industry standard protocols ranging from wired RS485 Modbus, 4-20mA, and HART to wireless protocols including WirelessHART, ISA100 and long range radios.

For more remote locations we offer flexible cellular and satellite options and in instances where power is not available onsite these can be paired with energy harvesting options such as solar panels with battery backup to ensure uninterrupted, round the clock monitoring.

A fixed platform version is also available for clients that prefer the security of non-cloud-hosted data. Connect corrosion probes, permanent UT sensors, injection pump controllers, tank level monitors and most flow control devices and start monitoring by exception.